Computer Vision-based Anomaly Detection System

Our computer vision-based anomaly detection system redefines glass manufacturing for NSG, swiftly identifying beading anomalies in real time. Tailored exclusively for NSG, it minimizes material wastage, optimizes operational efficiency, and ensures quality.

The Requirement

NSG Group, a global leader in glass and glazing, faced challenges in detecting anomalies during their glass production processes, particularly beading that led to glass breakage. The company sought a digital solution to swiftly and accurately identify beading occurrences, prevent glass breakage, minimize material wastage, and optimize operational efficiency.

The Solution

LeewayHertz collaborated with NSG Group to develop a robust AI-powered solution tailored for early anomaly detection in glass manufacturing. The solution focused on identifying beading anomalies in real time, enabling timely alerts to operators and proactive intervention. This tailored approach played a crucial role in cutting costs through the reduction of material wastage, streamlining operational efficiency, and elevating the overall product quality for NSG Group.

Features of the Solution

Real-time Anomaly Detection

The solution swiftly identifies beading in live video feeds, allowing for immediate operator intervention during the manufacturing process.

Strategic Adjustment

Enhances functionality by triggering alerts precisely at the fourth second of the beading cycle, ensuring highly accurate detection.

Accurate Anomaly Detection Alert

Provides precise and accurate alerts upon detecting anomalies, minimizing potential false alarms and ensuring timely operator response.

Benefits of the Solution

Responsive Alerts

Accurate anomaly detection alerts provide prompt and precise information, enabling operators to take immediate corrective action.

Operational Optimization

Timely interventions and adjustments improved overall operational efficiency in glass manufacturing.

Quality Enhancement

Ensured a higher standard of product quality, reducing defects and bolstering the company’s reputation.

Proactive Maintenance

Streamlined maintenance and planning processes, reducing unexpected downtime and facilitating improved resource allocation.

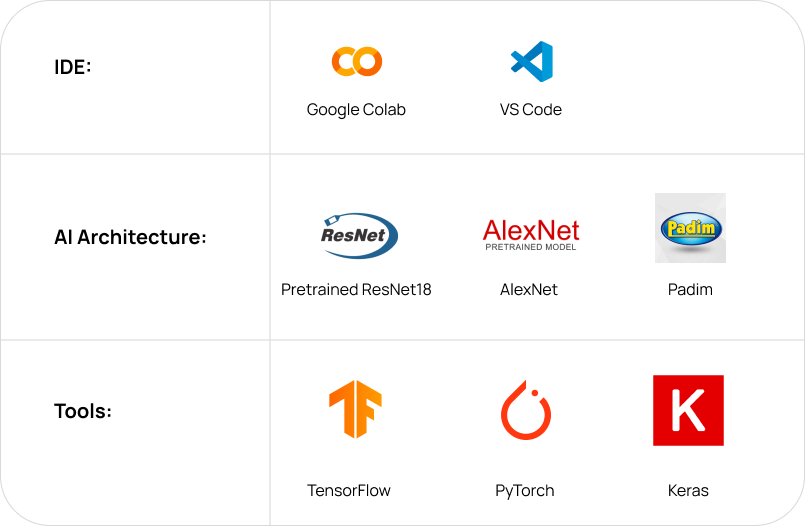

Technologies Used to Build the Anomaly Detection System