Beyond Traditional Logistics: Streamline Automotive Supply Chain Optimization Strategies Using AI

Impact of Data Overload in the Automotive Supply Chain

Achieving optimal efficiency in the supply chain is a critical success factor for the automotive industry. However, the process can be daunting due to the extensive and diverse data involved, often leading to data overload that can hinder decision-making and impede progress. This overload can result in delays, inaccuracies, and missed opportunities, emphasizing the urgent need for effective data management strategies. Moreover, the automotive industry also faces challenges balancing cost-effectiveness with the constant pressure to innovate and adapt to ever-evolving market demands for sustainable and eco-friendly practices.

I. How ZBrain Streamlines Supply Chain Optimization

ZBrain leverages advanced artificial intelligence and machine learning capabilities to automate the process of supply chain optimization. Here’s a comparison of the steps with and without ZBrain:

|

Steps |

Without ZBrain |

Time Without ZBrain |

With ZBrain |

|---|---|---|---|

| Data acquisition | Manual | ~5 hours | Automated by ZBrain |

| Data cleaning and preparation | Manual | ~8 hours | Automated by ZBrain |

| Data analysis | Manual | ~10 hours | Automated by ZBrain |

| Optimization report generation | Manual | ~10 hours | Automated by ZBrain |

| Report finalization | Manual | ~3 hours | Manual |

| Total | ~36 hours | ~3 hours |

The table shows that ZBrain significantly reduces the time spent on supply chain optimization from approximately 36 hours to just around 3 hours, resulting in substantial time and cost savings.

II. Key Input Data for ZBrain Flow

For optimal performance and precise optimization, ZBrain relies on the following data:

|

Information Source |

Description |

Recency |

|---|---|---|

| Production data | Records of production schedules and timelines | Real-time |

| Inventory data | Information on current stock levels and product demand | Always updated |

| Supplier data | Data on supplier reliability, lead times, and cost | Real-time |

| Distribution data | Information on distribution centers, logistics, and shipping | Real-time |

III. ZBrain’s Supply Chain Optimization: How It Works

Step 1: Data Collection and Integration

ZBrain automates data collection from diverse sources, such as production records, inventory data, supplier details, and distribution logs, to kickstart the automotive supply chain optimization process. This data is then seamlessly integrated into a centralized database, offering a comprehensive view of the entire supply chain.

Step 2: Exploratory Data Analysis (EDA) for Data Understanding

Before proceeding with the evaluation, ZBrain performs an automated Exploratory Data Analysis (EDA) on the collected data. This crucial step involves uncovering the data’s underlying structure and identifying missing values, outliers, correlations, and patterns that may impact the final evaluation process. The insights gained from EDA ensure that the data utilized is highly relevant.

Step 3: Embedding Generation

In this stage, the collected data that underwent the EDA process undergoes a transformation into numerical representations through advanced techniques. By employing these embeddings, ZBrain effectively analyzes the relationships and patterns within the data, setting the stage for meaningful insights during the optimization process.

Step 4: Query Execution

Whenever a user submits a query for supply chain optimization, ZBrain fetches the relevant data based on the query requirements. This data, combined with the associated prompt template, is then fed to the OpenAI Language Model (LLM) to generate an optimal response.

Step 5: Final Output Generation

Upon generating the report through the LLM, ZBrain initiates data parsing to filter out any irrelevant information, ensuring the report is accurate and focused. The parsed data is thoughtfully structured, adhering precisely to the desired format, sections, and report guidelines.

By seamlessly integrating all the steps, ZBrain presents the final version of your supply chain optimization report, providing your team with invaluable insights to guide strategic decision-making, enhancing supply chain efficiency and reducing costs.

Enhanced Supply Chain Efficiency for Automotive Success

ZBrain’s supply chain optimization solution significantly empowers automotive companies to improve their supply chain efficiency. With ZBrain’s automated process, you can transform your automotive supply chain management from a laborious 36-hour ordeal to a swift 3-hour breeze, saving valuable time and resources.

Say goodbye to guesswork and embrace data-driven decision-making as ZBrain equips you with comprehensive insights and analytics. By streamlining operations and reducing costs, ZBrain’s custom applications pave the way for heightened operational efficiency, reinforcing your company’s competitive edge and fostering substantial business growth. Embrace ZBrain today and take your automotive supply chain optimization to new heights.

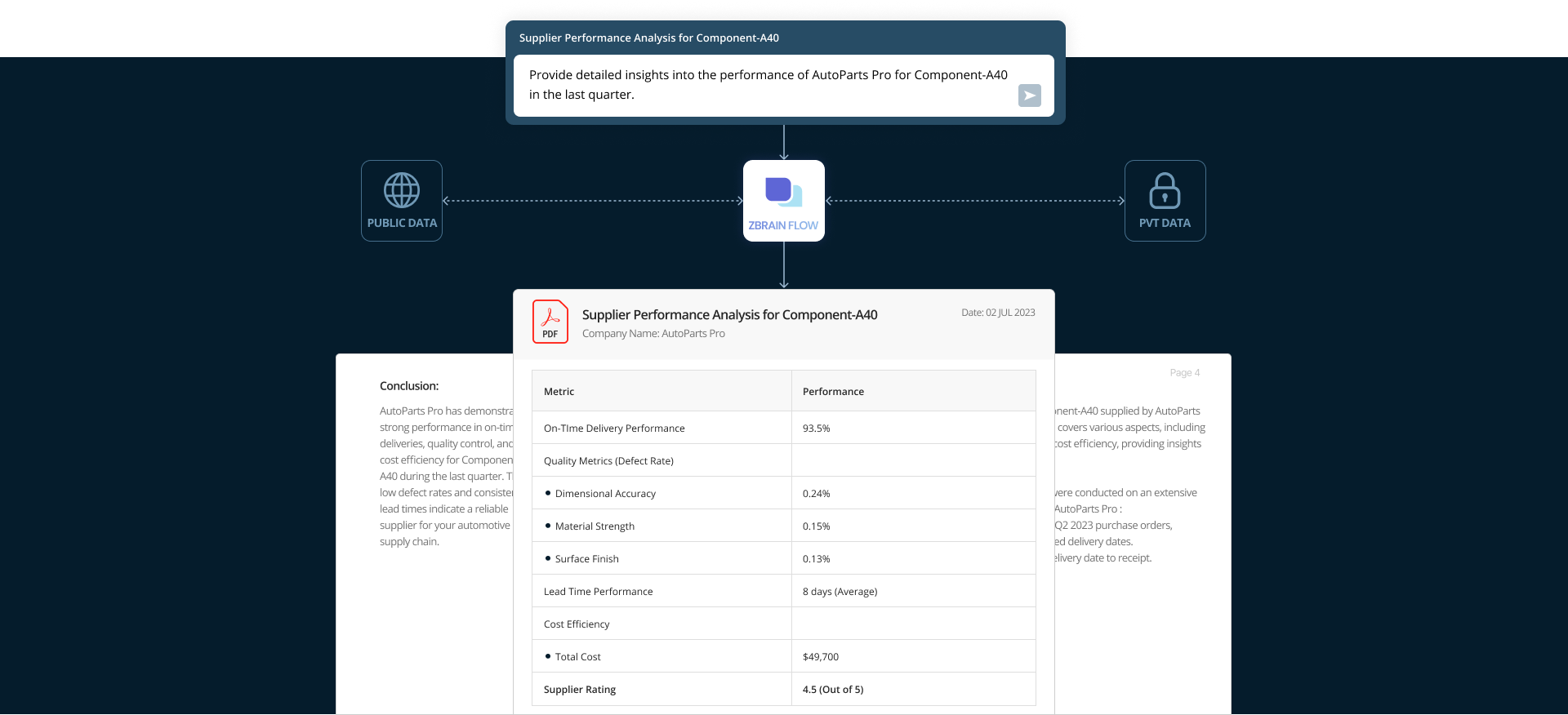

Prompt:

Provide detailed insights into the performance of AutoParts Pro for Component-A40 in the last quarter.

Supplier Performance Analysis for Component-A40 by AutoParts Pro

Executive Summary

This report presents a detailed analysis of Component-A40 supplied by AutoParts Pro during the last quarter, Q2 2023. The analysis covers various aspects, including on-time delivery, quality metrics, lead times, and cost efficiency, providing insights into the supplier’s performance.

Data Collection and Analysis

For the report’s creation, collection and analysis were conducted on an extensive dataset concerning Component-A40 supplied by AutoParts Pro :

-

Purchase Orders Data: Detailed records of all Q2 2023 purchase orders, including order dates, quantities, and requested delivery dates.

-

Delivery Performance Data: Tracking actual delivery dates compared to requested dates to calculate the on-time delivery rate.

-

Quality Control Data: Gathered information on received component quality, including defective units and total units for specific quality metrics.

-

Lead Time Data: Calculating lead times for each order, measuring time from order placement to receipt.

-

Cost Data: Collecting cost data, including production, transportation, and holding costs for Component-A40.

Methodology

-

On-time Delivery Analysis: Determining the on-time delivery rate by comparing delivery and order data.

-

Quality Metrics Analysis: Calculating defect rates for each quality metric by dividing defective units by total units received.

-

Lead Time Analysis: Measuring lead times by subtracting order placement dates from delivery dates.

-

Cost Efficiency Analysis: Computing the total cost for Component-A40 in Q2 2023 by combining production, transportation, and holding costs.

On-time Delivery Performance

|

Month

|

Orders Placed

|

Orders Delivered On Time

|

On-time Delivery Rate (%)

|

|---|---|---|---|

| April | 150 | 138 | 92.0% |

| May | 160 | 154 | 96.3% |

| June | 155 | 143 | 92.3% |

The on-time delivery rate for AutoParts Pro averaged 93.5% during Q2 2023, indicating a strong performance in meeting delivery timelines for Component A40.

Quality Metrics

|

Metric

|

Defective Units

|

Total Units Produced

|

Defect Rate (%)

|

|---|---|---|---|

| Dimensional Accuracy | 12 | 5,000 | 0.24% |

| Material Strength | 8 | 5,200 | 0.15% |

| Surface Finish | 6 | 4,800 | 0.13% |

AutoParts Pro maintained a commendable quality standard with low defect rates across key quality metrics during Q2 2023.

Lead Time Performance

The average lead time for Component-A40 from AutoParts Pro during the last quarter was 8 days, ensuring a timely supply chain.

Cost Efficiency

|

Cost Category

|

Cost (in USD)

|

|---|---|

| Production Cost | $45,000 |

| Transportation | $3,200 |

| Holding Cost | $1,500 |

| Total Cost | $49,700 |

AutoParts Pro incurred a total cost of $49,700 for supplying Component-A40 during Q2 2023.

Supplier Rating (Out of 5)

AutoParts Pro has earned an overall rating of 4.5 for Q2 2023.

Conclusion

AutoParts Pro has demonstrated strong performance in on-time deliveries, quality control, and cost efficiency for Component-A40 during the last quarter. The low defect rates and consistent lead times indicate a reliable supplier for your automotive supply chain.