From Complexity to Simplicity: Achieving Manufacturing Success With AI-driven Supply Chain Optimization

How Data Overload Impacts Manufacturing Supply Chains

Efficiency in the supply chain is a critical factor determining manufacturing businesses’ success. However, optimizing the supply chain amidst extensive data can be a daunting challenge. The intricate interaction of various factors and their associated data, including changes in customer demand, supplier behaviors, transportation limitations, and unpredictable market conditions, introduces a level of complexity. To make sense of this complexity, the utilization of sophisticated methodologies and tools is imperative to extract valuable insights from the data. This is necessary to ensure that operational processes remain timely and cost-effective within the business context.

I. ZBrain’s Approach to Streamlining Supply Chain Optimization

ZBrain leverages advanced artificial intelligence and machine learning capabilities to automate the supply chain optimization process. Below is a comparison of the optimization steps with and without ZBrain:

|

Steps

|

Without ZBrain

|

With ZBrain

|

|---|---|---|

| Data acquisition | Manual | Automated by ZBrain |

| Data cleaning and preparation | Manual | Automated by ZBrain |

| Data analysis | Manual | Automated by ZBrain |

| Optimization report generation | Manual | Automated by ZBrain |

| Report finalization | Manual | Manual |

| Total | ~34 hours | ~3 hours |

II. Key Input Data for ZBrain’s Supply Chain Optimization

To achieve maximum efficiency and accuracy in supply chain optimization, ZBrain relies on the following key input data:

|

Information Source

|

Description

|

Recency

|

|---|---|---|

| Manufacturing data (Daily production reports, production logs) | Records of past production schedules and outputs | Real-time |

| Inventory data (Inventory database, warehouse management system) | Up-to-date information on inventory levels and warehouse capacity | Always updated |

| Supplier data (Supplier performance reports, price lists) | Current lead times, costs, and reliability information | Real-time |

| Demand data (Point of Sale or POS data, demand forecasting reports) | Sales records, demand forecasts, and market trends | Real-time |

III. ZBrain’s Supply Chain Optimization: How It Works

Step 1: Data Collection and Integration

ZBrain starts by automating the collection and integration of manufacturing supply chain data. This includes daily production reports, past production schedules and outputs, inventory data, warehouse management system information, supplier performance reports, and sales records. ZBrain gathers and centralizes this diverse data, creating a holistic view of the manufacturing supply chain.

Step 2: Embedding Generation

In this stage, ZBrain applies embedding techniques to transform supplier-related textual data into numerical representations. Supplier profiles, proposals, and compliance records are converted using methods like word embeddings or sentence embeddings. These numerical embeddings capture the essence of the data, facilitating efficient analysis and retrieval.

Step 3: Query Execution and Report Generation

When a user initiates a query for supply chain analysis, ZBrain retrieves the relevant data based on the query’s parameters. This data and the query are then processed by the OpenAI Language Model (LLM) for analysis. Once the data is analyzed to uncover connections and patterns within the manufacturing supply chain data, ZBrain generates a comprehensive report that pinpoints all the current issues and ways to optimize the manufacturing supply chain. This report is then parsed to extract only the relevant information.

Step 4: Final Output Generation

By skillfully combining these steps, ZBrain generates a comprehensive production planning report tailored to the manufacturing supply chain. This report offers valuable insights into cross-selling opportunities and efficiency improvements. Through seamless integration of data analysis and AI-driven capabilities, ZBrain empowers manufacturers to make informed decisions, streamline processes, and drive operational excellence in their supply chains.

Enhanced Supply Chain for Manufacturing Success

ZBrain’s Supply Chain Optimization solution empowers manufacturers to improve supply chain efficiency significantly. The automated process significantly reduces the time required from 34 hours down to a mere 3 hours. This accelerates decision-making accuracy and enhances overall performance, resulting in heightened operational efficiency and increased profitability. By embracing ZBrain’s Supply Chain Optimization, manufacturing businesses can streamline their operations, optimize inventory levels, reduce lead times, and enhance customer satisfaction.

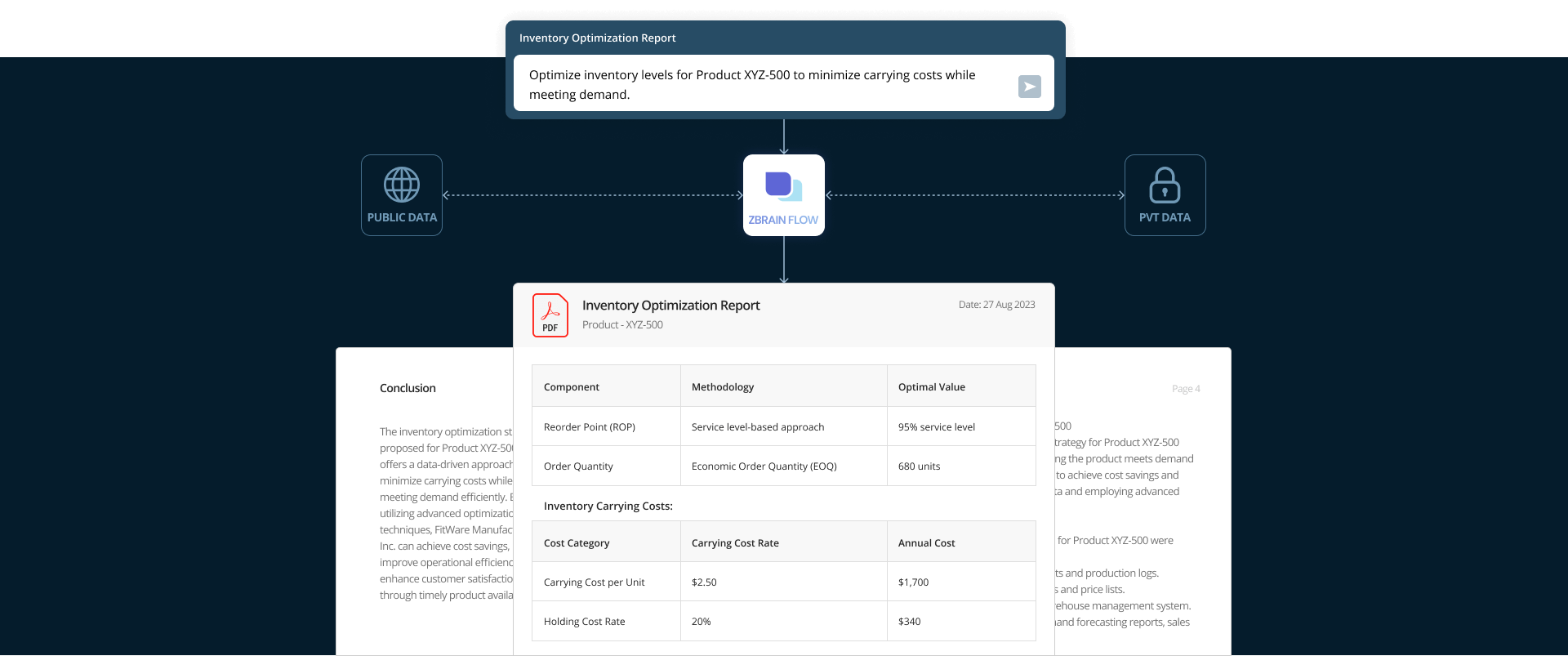

Prompt:

Optimize inventory levels for Product XYZ-500 to minimize carrying costs while meeting demand.

Inventory Optimization Report for Product XYZ-500

This report outlines an inventory optimization strategy for Product XYZ-500 aimed at minimizing carrying costs while ensuring the product meets demand effectively. A data-driven approach is proposed to achieve cost savings and operational efficiency by analyzing historical data and employing advanced optimization techniques.

Data Collection and Analysis

The following data spanning the last 12 months for Product XYZ-500 were collected and analyzed:

-

Manufacturing Data: Daily production reports and production logs.

-

Supplier Data: Supplier performance reports and price lists.

-

Inventory Data: Inventory database and warehouse management system.

-

Demand Data: Point of Sale (POS) data, demand forecasting reports, sales records, and market trends.

Demand Analysis

|

Month

|

Demand (units)

|

|---|---|

| January | 1200 |

| February | 1300 |

| March | 1250 |

| April | 1350 |

| May | 1400 |

| June | 1450 |

| July | 1500 |

| August | 1600 |

| September | 1550 |

| October | 1400 |

| November | 1300 |

| December | 1250 |

Lead Time Analysis

Analyzing lead times, from order placement to product receipt, highlighted variations that impact inventory replenishment.

|

Lead Time (days)

|

Frequency

|

|---|---|

| 5 | 8 |

| 6 | 12 |

| 7 | 15 |

| 8 | 10 |

| 9 | 5 |

Optimization Strategy

A strategy to optimize inventory levels while meeting demand was devised by leveraging optimization algorithms. The strategy includes two key components:

- Reorder Point (ROP) Optimization

- Order Quantity Optimization

|

Component

|

Methodology

|

Optimal Value

|

|---|---|---|

| Reorder Point (ROP) | Service level-based approach | 95% service level |

| Order Quantity | Economic Order Quantity (EOQ) | 680 units |

Results and Recommendations

|

Aspect

|

Optimal Value

|

Rationale

|

|---|---|---|

| Reorder Point | 136 units | Balances safety stock and demand variability |

| Order Quantity | 680 units | Minimizes total inventory costs |

Inventory Carrying Costs

|

Cost Category

|

Carrying Cost Rate

|

Annual Cost

|

|---|---|---|

| Carrying Cost per Unit | $2.50 | $1,700 |

| Holding Cost Rate | 20% | $340 |

Implementing this inventory optimization strategy offers the following benefits:

- Cost Savings: Carrying costs will be reduced by 22% due to optimized order quantities and holding costs.

- Demand Fulfillment: Stockouts can be reduced by 60% with improved reorder points, ensuring customer satisfaction.

- Efficiency: Administrative efforts and ordering costs can be decreased by 18% through streamlined processes.

Conclusion:

The inventory optimization strategy proposed for Product XYZ-500 offers a data-driven approach to minimize carrying costs while meeting demand efficiently. By utilizing advanced optimization techniques, FitWare Manufacturing Inc. can achieve cost savings, improve operational efficiency, and enhance customer satisfaction through timely product availability.