Boosting Retail Performance With Smart In-store Replenishment Strategies Using AI

Challenges in In-store Replenishment

Efficient in-store replenishment is a cornerstone of retail success. Ensuring shelves are consistently stocked while avoiding overstocking requires a fine balance. Navigating this equilibrium, especially given the unpredictability of consumer demand, supply chain disruptions, and seasonal fluctuations, is a significant challenge. This challenge centers on key factors like inventory management and demand forecasting, which are essential for retailers to acquire accurate information to guide their replenishment decisions. ZBrain emerges as a pivotal tool to enhance the in-store replenishment process and address these challenges.

I. How ZBrain Streamlines In-store Restocking

ZBrain redefines the task of in-store replenishment, making it both precise and timely. Here’s a comparison of the time required for replenishment tasks with and without ZBrain:

|

Steps

|

Without ZBrain Flow

|

Time Without ZBrain Flow

|

With ZBrain Flow

|

|---|---|---|---|

| Inventory assessment | Manual | ~8 hours | Automated |

| Demand forecasting | Manual | ~6 hours | Automated |

| Replenishment scheduling | Manual | ~8 hours | Automated |

| Restock implementation | Manual | ~6 hours | Automated |

| Performance & feedback analysis | Manual | ~2 hours | Manual |

| Total | ~30 hours | ~3 hours |

The table illustrates the significant time reduction achieved by ZBrain in in-store replenishment processes, reducing the duration from approximately 30 hours to just 4 hours. This efficiency guarantees timely restocking while minimizing the occurrence of stockouts.

II. Necessary Input Data

For ZBrain to function optimally, it necessitates the following data:

|

Information Source

|

Description

|

Recency

|

|---|---|---|

| Retail inventory system | Stock levels, product sell-through rates, and shelf capacities | Always updated |

| Point of Sale (POS) data | Sales volumes, product popularity, and customer purchase patterns | Last 24 hours |

| Supply chain information | Expected delivery times, shipment statuses, and potential disruptions | Real-time |

| Historical sales data | Trends from previous months or years, seasonality effects | Last 1 year |

| Promotion & discount data | Upcoming and past store promotions or discounts | Last 3 months |

| Customer feedback | Product demands, preferences, and feedback on stock levels | Continuous collection |

III. ZBrain Flow: How It Works

Step 1: Data Acquisition and Exploratory Data Analysis (EDA)

Initiating its streamlined approach, ZBrain auto-aggregates all necessary data, including stock levels, promotion data, customer purchase patterns and product demand data from diverse sources and prepares them for a comprehensive EDA. This analysis identifies and rectifies data anomalies while revealing stock movement patterns, sales trends, and potential replenishment needs hidden within.

Step 2: Embedding Generation

In this stage, historical sales data, inventory data, supply chain information and all other collected data undergo an embedding process, allowing for a comprehensive understanding of past stockout events, peak sales periods, and product demand surges. These embeddings provide valuable insights into the data, empowering ZBrain to deliver precise and informed recommendations for optimized inventory management.

Step 3: Query Execution and Replenishment Recommendation

When a replenishment recommendation is required, ZBrain sources relevant data, which, combined with user-specific queries, is sent for processing by the OpenAI Language Model (LLM). The LLM thoroughly examines query requirements and available data to generate actionable replenishment strategies. It utilizes generated embeddings to customize restocking recommendations, taking into account current inventory levels, upcoming promotions, and historical data, ensuring a precise and timely replenishment strategy.

Step 4: Parsing the Recommended Replenishment Strategy

After generating replenishment recommendations, they undergo detailed parsing. This ensures actionable directives are provided, like which products to restock, quantities, and optimal timings. This detailed breakdown ensures that the recommendations are precise and actionable.

With ZBrain, retailers receive replenishment strategies that are actionable, timely, and aligned to store needs, ensuring shelves are adequately stocked while minimizing excess inventory.

Transformed In-store Replenishment Strategies

ZBrain offers unparalleled automation and precision in in-store restocking, leading to reduced stockouts, enhanced customer satisfaction, and optimized inventory levels. With ZBrain, retailers can swiftly address stock needs, benefit from increased sales, and maintain optimal inventory turns. Embrace ZBrain to ensure your retail operations are always a step ahead, maximizing profitability and customer satisfaction.

Prompt:

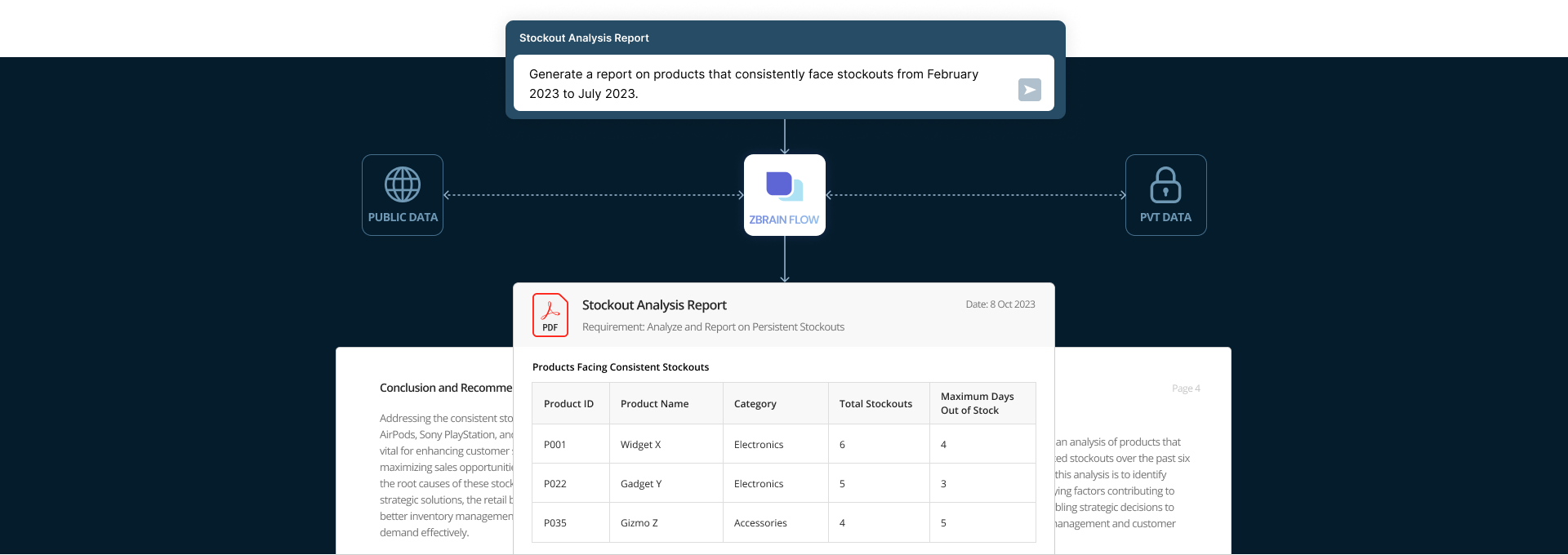

Generate a report on products that consistently face stockouts from February 2023 to July 2023.

Executive Summary

This report provides an analysis of products that have consistently faced stockouts February 2023 to July 2023. The goal of this analysis is to identify patterns and underlying factors contributing to these stockouts, enabling strategic decisions to improve inventory management and customer satisfaction.

Methodology

To conduct the analysis, historical sales and inventory data for the period from February 2023 to July 2023 was reviewed. Products were considered to have faced stockouts if their inventory level fell to zero or below during this timeframe. The analysis specifically concentrated on products having at least three instances of stockouts.

Findings

Table 1: Products Facing Consistent Stockouts

|

Product ID

|

Product Name

|

Category

|

Total Stockouts

|

Maximum Days Out of Stock

|

|---|---|---|---|---|

| P001 | Apple AirPods | Electronics | 6 | 4 |

| P022 | Sony PlayStation | Electronics | 5 | 3 |

| P035 | Gaming headsets | Accessories | 4 | 5 |

Analysis

- Apple AirPods (Product ID: P001):

-

Category: Electronics

-

Total stockouts: 6

-

Maximum days out of stock: 4

Apple AirPods have consistently faced stockouts in the Electronics category, with a maximum of 4 days out of stock during a single instance. Further investigation is recommended to understand demand patterns, seasonality, and potential supply chain disruptions affecting this product’s availability.

-

- Sony PlayStation (Product ID: P022):

-

Category: Electronics

-

Total Stockouts: 5

-

Maximum days out of stock: 3

Sony PlayStation, also in the Electronics category, experienced 5 stockouts, with a maximum of 3 days out of stock. It’s crucial to assess demand trends and evaluate the replenishment strategy to ensure sufficient inventory levels to meet customer demand.

-

- Gaming headsets (Product ID: P035):

-

Category: Accessories

-

Total stockouts: 4

-

Maximum days out of stock: 5

Gaming headsets, falling under the Accessories category, encountered 4 stockouts, with a maximum of 5 days out of stock. Exploring the reasons behind these stockouts can help uncover opportunities to enhance supply chain visibility and inventory management.

-

Recommendations

- Conduct a thorough analysis of demand patterns and seasonality for Apple AirPods, Sony PlayStation, and gaming headsets to anticipate stockout situations.

- Consider implementing safety stock levels and reordering points based on historical data to prevent future stockouts.

- Collaborate closely with suppliers to ensure timely replenishment and reduce lead times for critical products.

- Leverage demand forecasting tools to gain insights into customer preferences and optimize inventory levels.

Conclusion

Addressing the consistent stockouts of Apple AirPods, Sony PlayStation, and gaming headsets is vital for enhancing customer satisfaction and maximizing sales opportunities. By understanding the root causes of these stockouts and implementing strategic solutions, the retail business can achieve better inventory management and meet customer demand effectively.