Manufacturing

Boost Productivity, Save Time: Harness AI for Production Planning and Optimization

Current Production Planning and Scheduling Challenges

Are you struggling with production planning and scheduling inefficiencies? In the manufacturing industry, inaccurate forecasting, suboptimal resource allocation, and inadequate inventory management can lead to increased downtime, missed delivery deadlines, and excessive inventory carrying costs. Traditional approaches to production planning often lack the agility and accuracy required to meet dynamic market demands. With the transformative power of AI in production, ZBrain Flow offers a solution that reforms these processes, enhancing efficiency and precision to drive better outcomes for your business.

I. How ZBrain Flow Streamlines the Process

Say goodbye to the complexities of outdated production planning methods and embrace the future of manufacturing with ZBrain Flow. ZBrain empowers your business to utilize generative AI for production planning, reducing costs, increasing output, and seamlessly meeting market demands. Here’s the comparison table of the time required for each task with and without ZBrain Flow:

|

Steps |

Without ZBrain Flow |

Time Without ZBrain Flow |

With ZBrain Flow |

|---|---|---|---|

| Data collection | Manual | ~4 hours | Automated |

| Demand forecasting | Manual analysis | ~12 hours | AI-driven swift forecast |

| Resource allocation | Manual calculations | ~10 hours | AI-driven swift allocation |

| Scenario planning | Manual simulations | ~15 hours | AI-driven swift evaluation |

| Cost optimization | Manual cost analysis | ~10 hours | AI-driven cost analysis |

| Real-time insights | No real-time access | Delays in accessing data | Real-time data updates |

| Report generation | Manual | ~6 hours | Automated |

| Report review | Manual | ~4 hours | Manual |

| Total | ~65 hours | ~5 hours |

II. Necessary Input Data

|

Information Source |

Description |

Recency |

|---|---|---|

| Historical production data | Information on past production cycles, output quantities, and resource usage. | Most recent data |

| Sales and demand data | Customer demand patterns, sales orders, and market demand forecasts. | Up-to-date information |

| Inventory data | Inventory levels and stock availability for efficient material planning. | Last 1 year |

| Resource data | Available machines, equipment, and workforce details, including capacities. | Current resource data |

| Supplier data | Information on suppliers, lead times, and pricing for effective supply chain. | Recent supplier data |

| Cost data | Production costs, raw material costs, labor expenses, and overhead costs. | Current cost figures |

| Market data | Market trends, competitor activities, and industry developments. | Latest market updates |

| External factors | External factors that can influence production (e.g., weather, regulations). | Real-time information |

| Real-time data streams | Continuous updates on production performance and machine statuses. | Real-time streaming |

III. ZBrain Flow: How It Works

Step 1: Data Acquisition and Exploratory Data Analysis (EDA):

The primary step in an effective production planning process involves data collection, a task efficiently managed by ZBrain Flow. ZBrain automatically collects relevant data such as production history, demand forecasts, inventory records, machine downtime, and maintenance schedules.

After gathering the data, ZBrain conducts an automated Exploratory Data Analysis (EDA) to extract meaningful insights. EDA entails understanding the data structure and identifying missing values, outliers, correlations, and patterns that can influence production planning.

Step 2: AI-Driven Embedding Generation

In this stage, textual data (production history, inventory data, market data) is transformed into numerical representations using embedding techniques. These embeddings capture the contextual relationships between different data points, facilitating efficient retrieval and analysis. This seamless transformation allows ZBrain to provide insights with exceptional precision, enhancing your decision-making process.

Step 3: Query Execution and Report Generation

When you submit a query for production planning, ZBrain fetches relevant data based on your requirements. This data and the query are then passed on to the OpenAI Language Model (LLM) for further analysis. ZBrain analyzes historical data and market trends to provide accurate demand forecasting. This helps ensure the right workforce allocation, raw materials, and equipment to meet production targets efficiently. The LLM comprehends and contextualizes the data, dynamically generating a comprehensive and coherent report text based on your inputs.

Step 4: Performance Metrics and Feedback Loop

ZBrain generates performance metrics and reports for production efficiency and effectiveness. Key performance indicators (KPIs) are automatically calculated, giving manufacturers valuable insights into their production performance. ZBrain’s feedback loop allows stakeholders to provide inputs and suggestions, which are incorporated into the production planning process.

Step 5: Expert Parsing of the Generated Report

As per the user query, the reports generated in text format undergo meticulous parsing. ZBrain expertly extracts essential information. The parsed data is thoughtfully structured to adhere precisely to the desired format, sections, and report guidelines.

Step 6: Final Output Generation

Once the production plan is generated in text format, a detailed parsing process is initiated, adeptly extracting critical information like production schedules, inventory management plans, and conclusions. This parsed data is then structured meticulously, ensuring the final plan conforms strictly to the desired format and guidelines.

Automated Production Planning and Optimization

ZBrain Flow enhances production planning and optimization in a manufacturing firm, reducing the time and effort required for decision-making processes. With its AI-powered capabilities, the traditional planning tasks that used to take approximately 65 hours are now streamlined to just around 5 hours, resulting in significant time and cost savings. Leverage the AI-powered capabilities of ZBrain Flow to boost efficiency, helping your organization meet market demands with precision using AI for production planning.

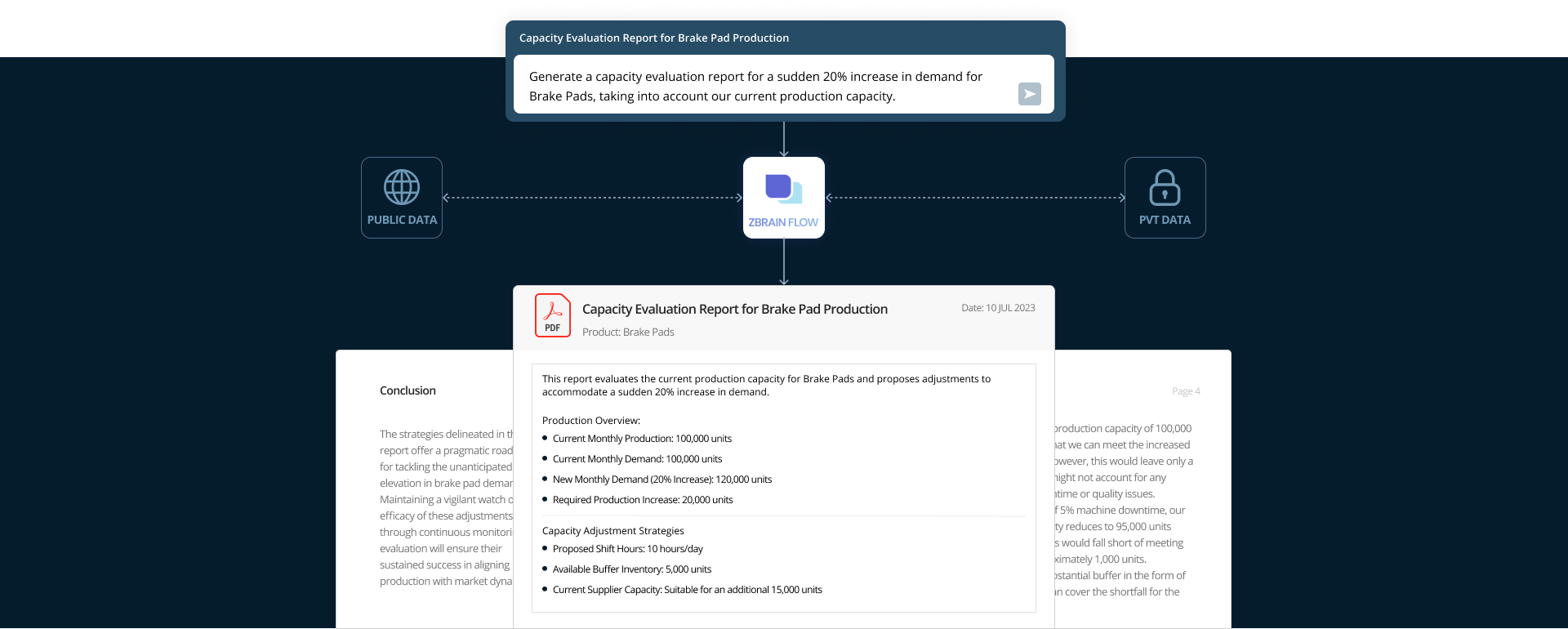

Prompt:

Generate a capacity evaluation report for a sudden 20% increase in demand for Brake Pads, taking into account our current production capacity.

Capacity Evaluation Report for Brake Pad Production

Executive Summary:

This report evaluates the current production capacity for brake pads and outlines the necessary adjustments to meet a sudden 20% increase in demand. To derive a comprehensive plan, we have assessed various aspects, including current production levels, inventory status, supplier capacity, and resource allocation.

- Introduction:

The brake pads constitute a critical component within the automotive industry, and the sudden 20% upsurge in demand necessitates strategic considerations. This report meticulously examines the current production landscape and proposes pragmatic adjustments to meet the heightened requisites.

- Current Capacity Analysis:

2.1 Current Production Capacity:

-

Current Monthly Production: 100,000 units

-

Current Monthly Demand: 100,000 units

-

New Monthly Demand With 20% Increase: 120,000 units

-

Required Increase in Production: 20,000 units

|

Parameter

|

Value

|

|---|---|

| Current Production (Q4) | 100,000 |

| Demand Forecast (Q4) | 100,000 |

| New Demand Forecast (Q4) | 120,000 |

| Required Increase | 20,000 |

2. 2 Demand Forecast Analysis:

We have analyzed the historical data, market trends, and potential influencing factors to project the 20% surge in brake pad demand. This ensures that the demand surge is both credible and actionable.

2.3 Inventory Assessment:

We can understand the buffer available to bridge the demand gap during production adjustments by assessing the existing brake pad inventory levels.

- Identifying Demand Factors:

The 20% surge in brake pad demand may be attributed to diverse factors such as seasonal fluctuations, strategic marketing endeavors, or market expansion initiatives.

- Capacity Adjustment Strategies:

4.1 Increase Shift Hours:

- Current Shift Hours: 8 hours/day

- Proposed Shift Hours: 10 hours/day

4.2 Utilize Buffer Inventory:

- Available Buffer Inventory: 5,000 units

4.3 Supplier Engagement:

-

Current Supplier Capacity: Sufficient for an additional 15,000 units

- Recommendations:

We recommend the implementation of the following strategies:

-

Swift implementation of extended shift hours.

-

Prudent utilization of buffer inventory to meet surges.

-

Proactive engagement with suppliers for seamless raw material procurement.

-

Rigorous adherence to stringent quality control protocols.

- Implementation Plan:

-

Weeks 1-2: Initiate communication with suppliers and outline shift adjustment plans.

-

Weeks 3-4: Implement extended shift hours and evaluate initial production outcomes.

-

Weeks 5-6: Maximize buffer inventory use and gauge its impact on production.

Continuous monitoring of production output, supplier performance, and quality control measures will be essential to ensure the success of the adjustment strategies.

Conclusion:

The strategies delineated in this report offer a pragmatic roadmap for tackling the unanticipated 20% elevation in brake pad demand. Maintaining a vigilant watch on the efficacy of these adjustments through continuous monitoring and evaluation will ensure their sustained success in aligning production with market dynamics.