Precision in Motion: Enhancing Automotive Quality Control Using AI

Quality Control and Defect Analysis Using ZBrain

Data Overload in Automotive Quality Control

Maintaining high-quality control standards and effective defect analysis are critical elements for success in the automotive industry. However, with modern automobiles’ increasing complexity and sophistication, the amount of data involved in these processes has grown exponentially, making them increasingly challenging. Manually analyzing this massive volume of data is a laborious and time-consuming task, prone to errors and inefficiencies. Moreover, the demand for data-driven insights becomes even more critical as the automotive industry progresses toward more intelligent and autonomous vehicles.

I. How ZBrain Streamlines Quality Control and Defect Analysis

ZBrain uses advanced artificial intelligence and machine learning capabilities to automate the automotive industry’s quality control and defect analysis processes. Here’s a comparison of these processes with and without ZBrain:

|

Steps |

Without ZBrain |

Time Without ZBrain |

With ZBrain |

|---|---|---|---|

| Data acquisition | Manual | ~5 hours | Automated |

| Data cleaning and preparation | Manual | ~8 hours | Automated |

| Data analysis | Manual | ~10 hours | Automated |

| Defect prediction report generation | Manual | ~10 hours | Automated |

| Report review and finalization | Manual | ~3 hours | Manual |

| Total | ~36 hours | ~3 hours |

As the table shows, ZBrain reduces the time spent on quality control and defect analysis from around 36 hours to just about 3 hours, yielding significant time and cost savings.

II. Key Input Data for ZBrain

For optimal performance and accurate predictions, ZBrain relies on the following data:

|

Information Source |

Description |

Recency |

|---|---|---|

| Manufacturing data | Records of production schedules, methodologies, and parameters | Real-time |

| Inspection data | Detailed results of product inspections and tests | Always updated |

| Supplier data | Information on part specifications, supplier reliability, and delivery times | Real-time |

| Warranty data | Records of warranty claims and customer feedback | Real-time |

III. ZBrain’s Quality Control and Defect Analysis: How It Works

Step 1: Data Acquisition

Acquiring relevant data is the foundation of effective quality control and defect analysis. ZBrain seamlessly collects data from multiple sources, including production lines, inspection results, supplier data, and warranty claims. This automated data acquisition process ensures a comprehensive dataset is available for analysis.

Step 2: Exploratory Data Analysis (EDA)

Once the data is gathered, ZBrain initiates an exploratory data analysis (EDA) to unveil valuable insights. EDA involves understanding the structure of the data, identifying patterns, correlations, and potential defect indicators. This essential step helps identify areas that require further investigation and sets the foundation for meaningful defect analysis.

Step 3: Embedding Generation

ZBrain employs advanced embedding techniques to transform textual data related to quality control and defects into numerical representations to empower efficient data analysis. These embeddings capture the semantic meaning and relationships between different data points, facilitating easy retrieval and analysis.

Step 4: Query Execution

Upon receiving a quality control or defect analysis query, ZBrain initiates a seamless data retrieval process, fetching the relevant data based on the query requirements. The retrieved data and the query are then seamlessly passed on to the powerful OpenAI Language Model (LLM) for intelligent report generation.

By drawing insights from the dataset, query specifics, and the desired report structure, the OpenAI LLM dynamically crafts a comprehensive and coherent report text and generates a response.

Step 5: Final Output Generation

Integrating all the steps, ZBrain produces the final version of your quality control and defect analysis report. This report provides valuable insights that guide decision-making, leading to enhanced product quality and reliability.

Enhanced Quality Control for Automotive Success

ZBrain’s quality control and defect analysis solution significantly empowers automotive companies to improve product quality and reliability. By automating the process, the time required is cut down significantly from 36 to only 3 hours, facilitating precise decision-making, enhancing overall performance, and ultimately contributing to amplified customer satisfaction and business growth. Embrace ZBrain today and elevate your automotive quality control and defect analysis to new heights.

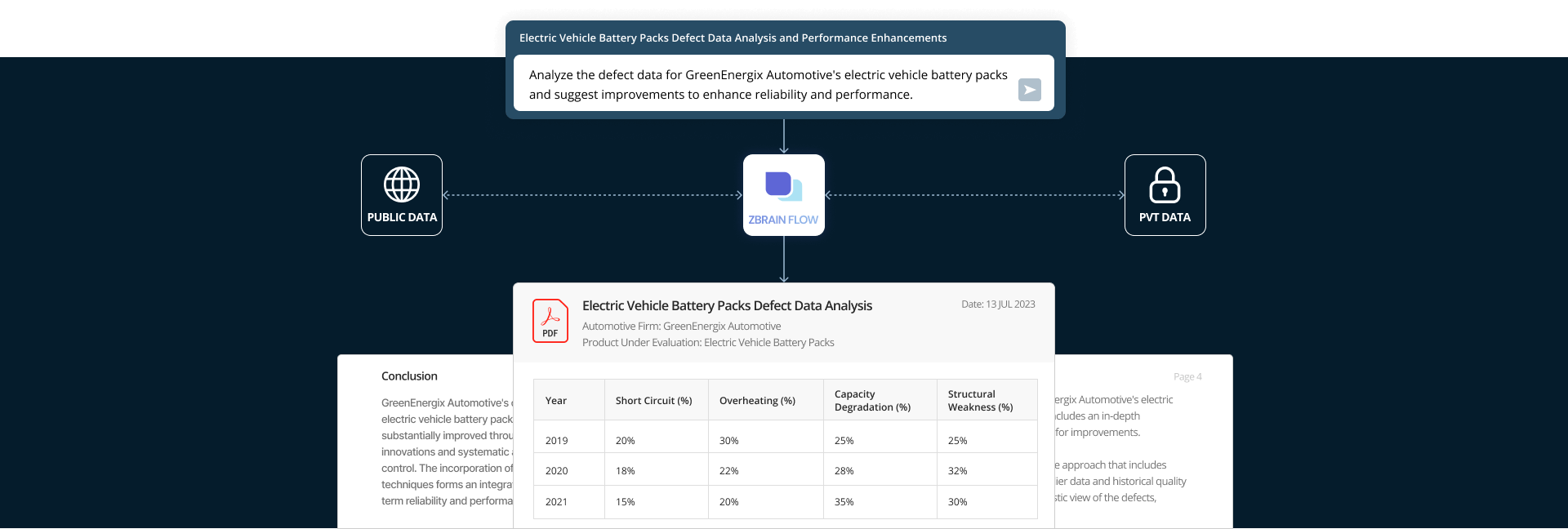

Prompt:

Analyze the defect data for GreenEnergix Automotive’s electric vehicle battery packs and suggest improvements to enhance reliability and performance.

Electric Vehicle Battery Packs Defect Data Analysis and Performance Enhancements

This report investigates the defect data associated with GreenEnergix Automotive’s electric vehicle (EV) battery packs for the past three years. The analysis includes an in-depth examination of the defects, their causes, and recommendations for improvements.

Data Gathering

The data for this analysis was gathered through a comprehensive approach that includes manufacturing line inspections, customer warranty claims, supplier data and historical quality reports. The amalgamation of these data sources ensures a holistic view of the defects, encompassing both manufacturing and real-world scenarios.

Defect Summary (2019-2022)

The following table summarizes the major defect categories and their corresponding counts for the past three years:

|

Year

|

Short Circuit (%)

|

Overheating (%)

|

Capacity Degradation (%)

|

Structural Weakness (%)

|

|---|---|---|---|---|

| 2019 | 20% | 30% | 25% | 25% |

| 2020 | 18% | 22% | 28% | 32% |

| 2021 | 15% | 20% | 35% | 30% |

Defect Analysis and Improvement Recommendations

- Overheating

Current Drawbacks:

-

Inefficient cooling systems have contributed to a significant percentage of overheating issues.

-

Existing technology relies on passive cooling techniques, which have proven to be ineffective during prolonged usage.

Suggested Improvements:

-

Implement advanced active cooling systems, such as Liquid Cooling Solutions (LCS), previously proven effective in industries requiring high thermal management.

- Short Circuit

Current Drawbacks:

-

The lack of robust insulation mechanisms leads to a high percentage of short circuits.

-

Existing technology utilizes standard insulation material, lacking proper monitoring systems.

Suggested Improvements:

-

Incorporate nano-coated insulating materials with enhanced resistance properties.

-

Implement intelligent monitoring systems with short-circuit detection algorithms.

- Capacity Degradation

Current Drawbacks:

-

Current charging cycles and materials cause rapid capacity degradation.

-

Lack of integration with Battery Management Systems (BMS) causing imbalanced charging.

Suggested Improvements:

-

Implementation of Lithium Iron Phosphate (LiFePO4) cells, which are known to have a higher life cycle.

-

Integrating an advanced BMS to monitor and control charging cycles, as seen with Tesla’s patented charging algorithms.

- Structural Weakness

Current Drawbacks:

-

Structural design has not kept pace with the evolving need for increased safety and stability.

-

Traditional structural materials and designs are used, leading to a percentage increase in structural weakness over time.

Suggested Improvements:

-

Implement advanced composite materials, such as carbon-fiber-reinforced polymers, which are lighter and more durable.

-

Utilize Finite Element Analysis (FEA) to optimize the structure for specific use cases.

Conclusion

GreenEnergix Automotive’s ongoing challenges with electric vehicle battery pack defects can be substantially improved through technological innovations and systematic approaches to quality control. The incorporation of advanced materials and techniques forms an integrated strategy for long-term reliability and performance enhancement.